DIY Electronic Speed Controller

Part I: Drawings and Procedure This homemade electronic speed controller (ESC) can be used in a radio controlled electric car, boat, or airplane. It is made by using an old servo, plus a couple of simple and easy-to-get electronic components.

It's a fun project because you get to recycle an unused servo, and possibly save a few bucks.

This ESC does not have reverse, nor a battery eliminator circuit (BEC).

Those with an electronics background can build this just from the drawing.

For the "rest of us" here's a simple procedure and photos of a finished controller. We've built a handful of these, so we'll try to guide you.

If you have no idea how to solder or what a resistor is, and don't care to learn, you might be better off buying your ESC already made...

1) MATERIALS

-Old servo. One with a broken gear train ("stripped") is ideal for this, as the servo electronics (amplifier board) will often be in good condition.

-Power Amplifier(s). A power amplifier is basically a transistor. MOSFETs will work for this purpose also. The recommended power amplifiers are MJ11032, or 2N6282. We've been using the latter, they come in a bag with NTE251 on the label.

Get these at your local electronics store (and we don't mean Circuit City! Look in the Yellow Pages for a store that sells circuit components). One (1) amplifier (and one resistor) will work; if you need to carry higher current, more amplifiers and resistors can be added (we'll discuss this more later). For the MOSFETs, IRF530 are reported to work.

-Resistor(s). 500 or 1000 ohm will work. From the same electronics store, or Radio Shack.

-Wire. 12 or 13 Gauge can handle ten's of Amps easily. The flexible silicone wire works best. If the electronics store doesn't have it, try the RC car section of the local hobby shop.

-Solder -Connectors. Two pairs of whatever connectors you currently use on your batteries and motors: PowerPoles, Deans, etc. -Optional: Circuit Mounting Board, Heat Sink, Zip ties

2) TOOLS

-Soldering Iron -Knife or wire cutter/stripper -small Philips screwdriver

3) PROCEDURE

-Use the screwdriver to dis-assemble the servo case. -Remove the servo gears. -Cut the wires to, and remove, the servo motor. -Leave the circuit board (amplifier) and pot in place. (The pot [potentiometer, or variable resistor] is the round thing with three terminals on the bottom. In the servo it's used as a feedback device to determine amount of travel).

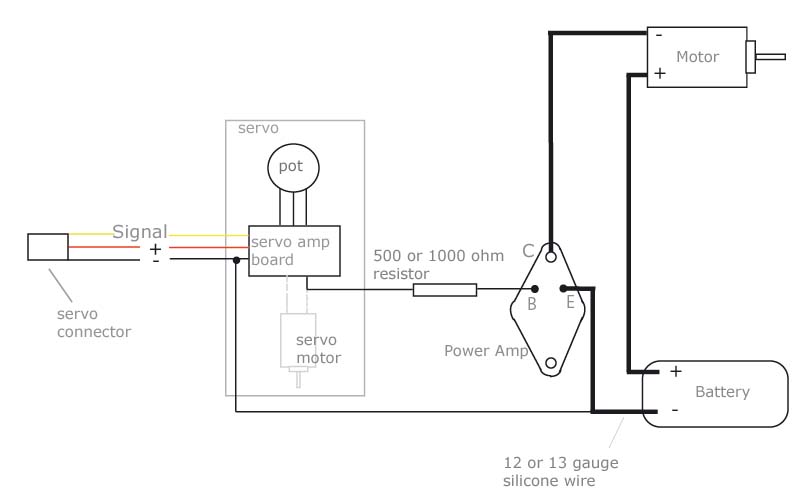

-Solder the components as shown in the diagram. The wires shown in bold need to be the high gauge wire (12 or 13), that's where most of the current is carried.

-On the power amp, the two pins on the underside are closer to one end than the other. The diagram shows the bottom side of the amp. The pins are labeled in the diagram as B (Base, or Gate), E (Emitter, or Source), and C (Collector, or Drain).

-One of the servo motor wires is soldered to a resistor. Wrap the other wire with tape.

-The negative terminal of the battery is connected to the negative wire of the servo connector. In most modern systems, the arrangement is: yellow (or white) is Signal, then red (or orange) is Positive (the middle wire) then black (or brown) is negative).

Be aware that some older systems had odd conventions (e.g. Airtronics, red outside is positive, black middle is negative, then black (again!) is signal. If in doubt find a wiring diagram in the radio system manual.

-Plug the servo connector into the throttle channel of the receiver. This ESC does not have a BEC, which means that you need to plug a separate receiver battery (usually 4 cell NiCd or NiMH) into the battery port of the receiver.

On to Part II: Tips and Photos.